Features

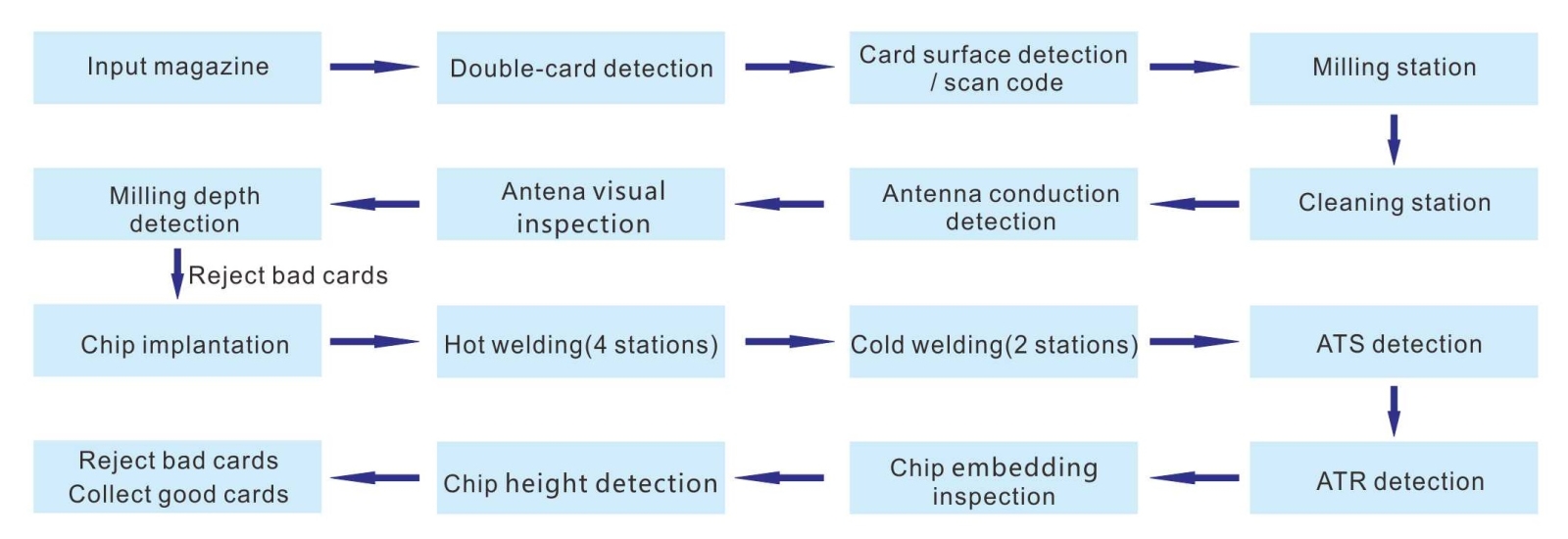

The milling depth accuracy is ±0.01 mm.

Convenient and simple to operate and maintain.

Equipped with detection device to avoid double card.

Equipped with a secondary cleaning function to ensure that

there is no residual scrap on the card surface.

Antenna conduction detection ensures the good performance

of the card and increases Yield.

4 stations hot welding +2 stations cold welding.

Equipped with ATR and ATS detection function, so as to find

abnormal packaging in time.

Bad cards will be detected and automatically collected.

Convenient and simple to operate and maintain.

Equipped with detection device to avoid double card.

Equipped with a secondary cleaning function to ensure that

there is no residual scrap on the card surface.

Antenna conduction detection ensures the good performance

of the card and increases Yield.

4 stations hot welding +2 stations cold welding.

Equipped with ATR and ATS detection function, so as to find

abnormal packaging in time.

Bad cards will be detected and automatically collected.